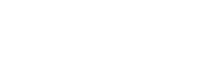

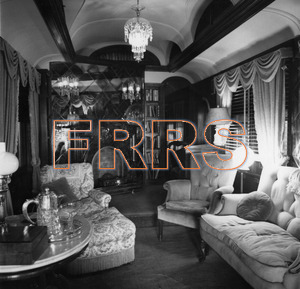

Lucius Beebe's private car Gold Coast Interior-01

(Mileposts March-April 1974)

|

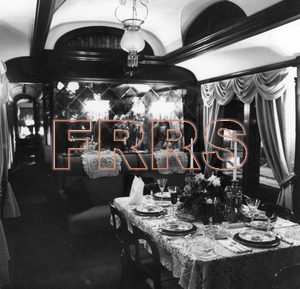

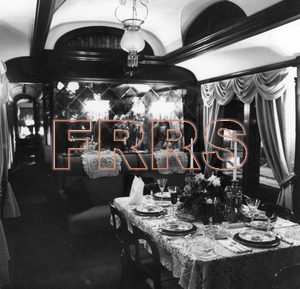

Lucius Beebe's private car Gold Coast Interior-02

(Mileposts March-April 1974)

|

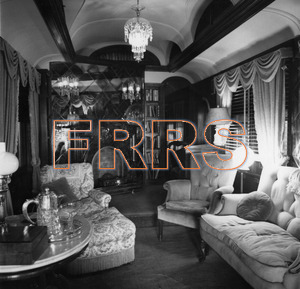

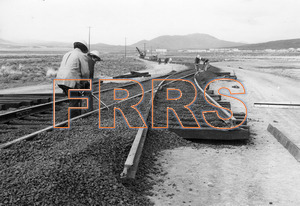

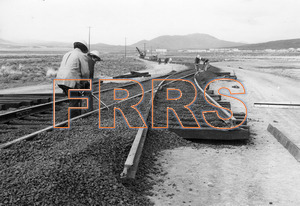

Reno Branch - A daily delivery of material including new pressure treated ties and rail are unloaded at the track assembly area.

(Mileposts Summer 1977)

|

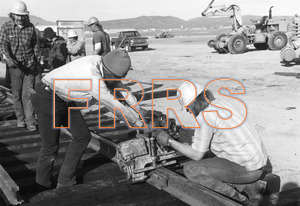

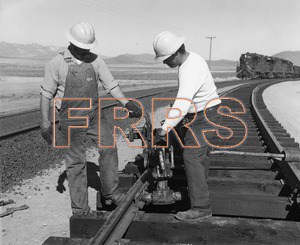

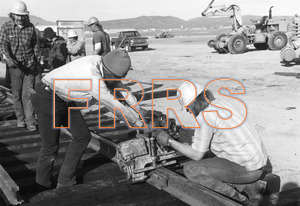

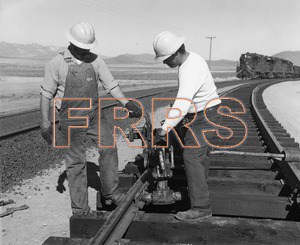

Reno Branch - Track gangs. install new joint bars using the drilling machine to make new bolt holes in rail.

(Mileposts Summer 1977)

|

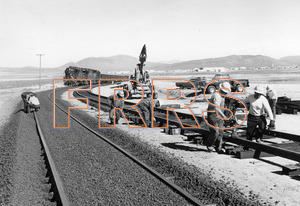

Reno Branch - Track Foreman directs tamper operator to raise track and tamp ballast to ensure good track surface.

(Mileposts Summer 1977)

|

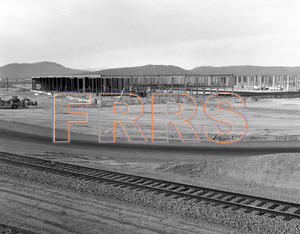

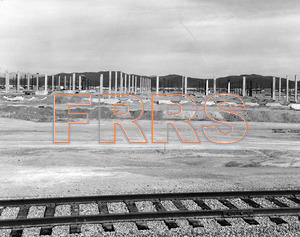

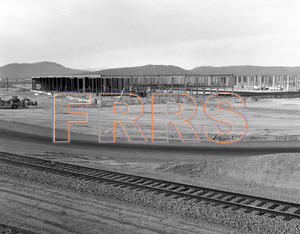

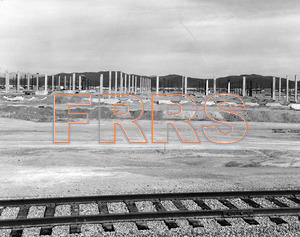

Reno Branch - With ballasting operations concluded on main track extension, the track gang is rapidly assembling the new run around track adjacent to the construction of the new J.C. Penney's distribution warehouse.

(Mileposts Summer 1977)

|

Reno Branch-05

|

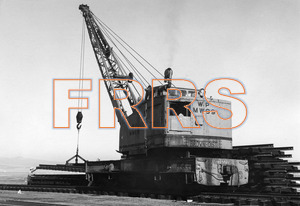

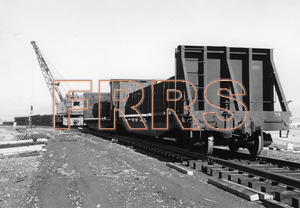

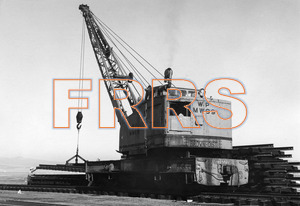

Reno Branch - WP-MW89 brown hoist crane places prefab panel on 'the stack' ready to be transported to the railhead.

(Mileposts Summer 1977)

|

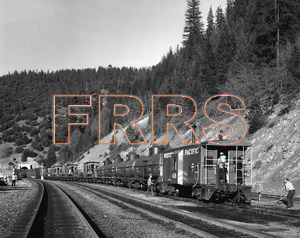

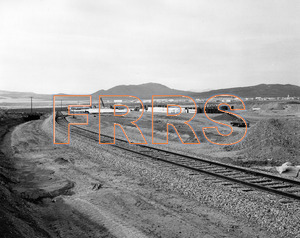

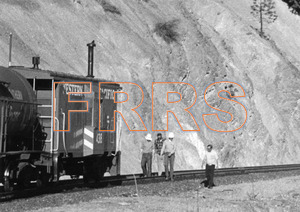

WP work train arrives on Reno Branch with 30 carloads of ballast ready to unload on the new line extension.

(Mileposts Summer 1977)

|

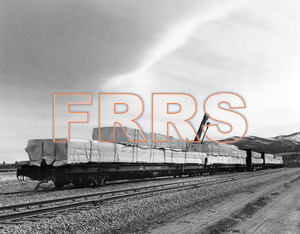

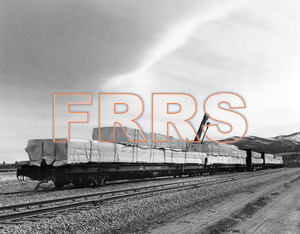

Reno Branch - The roof trusses are made of laminated wood beams and shipped on 85 ft. flatcars to the construction site.

(Mileposts Summer 1977)

|

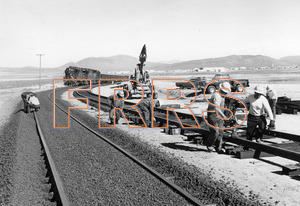

Reno Branch - Foreman Ed Lowe and extra gang 205 man the track panel assembly line with the assistance of air powered tools. These rnen can assernble 24 panels per day or about one panel every 20 minutes.

(Mileposts Summer 1977)

|

Reno Branch - Track gangs using a bolt tightening machine.

(Mileposts Summer 1977)

|

Reno Branch - WP-MW89 brown hoist crane places prefab panel on 'the stack' ready to be transported to the railhead.

(Mileposts Summer 1977)

|

Reno Branch - Photo shows the two switches from the run-around track that will serve the inside of the new warehouse. Also shown are rows of roof trusses that were unloaded from WP rail cars.

(Mileposts Summer 1977)

|

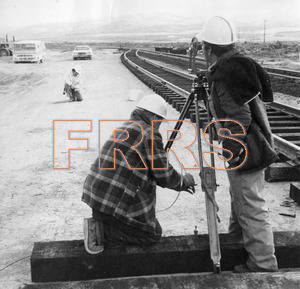

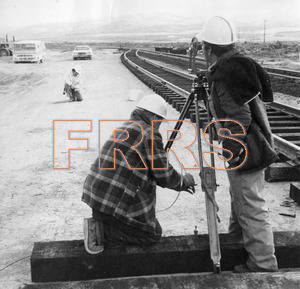

Reno Branch - Surveying Engineer Ray Santiago, right, and Field Engineer T. G. Rutherford stake out the new right·of·way and set alignment stake for the new track.

(Mileposts Summer 1977)

|

Reno Branch - Engineer Tony Giovannoni and the surveying team set a center line for the new track.

(Mileposts Summer 1977)

|

Reno Branch - In the drafting room at the San Francisco office, engineers review project plans regarding the Lear Reno track construction. Working at the drafting table are (I. to r.), Engineer Tony Giovannoni, Engineer Dick Frager and Engineer ·Plannmg and Design, L. E. Lelevich.

(Mileposts Summer 1977)

|

Reno Branch-16

|

Reno Branch-17

|

Reno Branch-18

|

Reno Branch-19

|

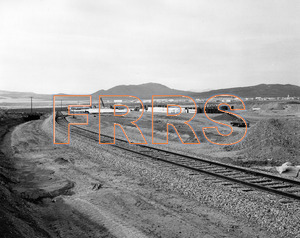

Reno Branch - Following final rail aligner,. tamping and grooming operations. the new industrial line extension is complete and ready for traffic.

(Mileposts Summer 1977)

|

Reno Branch - Photo shows the two switches from the run-around track that will serve the inside of the new warehouse. Also shown are rows of roof trusses that were unloaded from WP rail cars.

(Mileposts Summer 1977)

|

Reno Branch-22

|

Reno Branch - First commercial loads of building material are delivered to the siding. The materials include roof trusses for construction in the large new warehouse.

(Mileposts Summer 1977)

|

Reno Branch - First commercial loads of building material are delivered to the siding. The materials include roof trusses for construction in the large new warehouse.

(Mileposts Summer 1977)

|

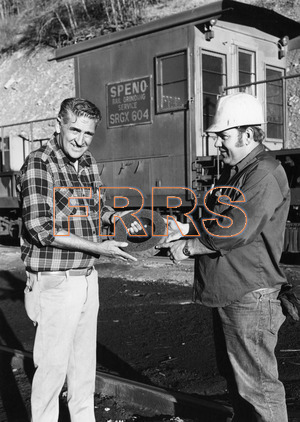

Speno Rail Grinding Train-01 3-18-77 Dale Sanders

|

Speno Rail Grinding Train-02 3-18-77 Dale Sanders

|

Speno Rail Grinding Train-03 Paul Gordenev

|

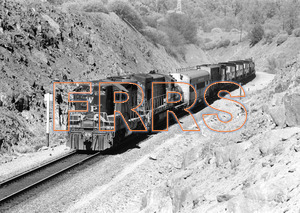

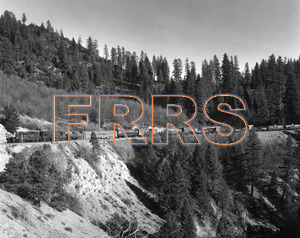

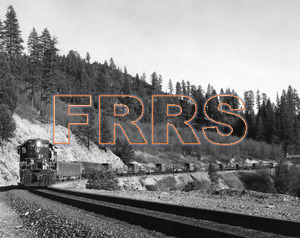

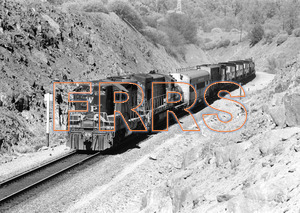

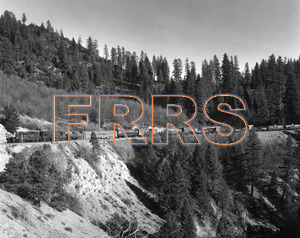

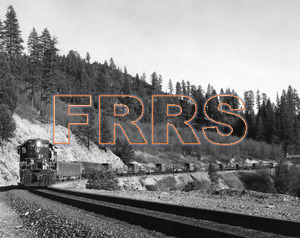

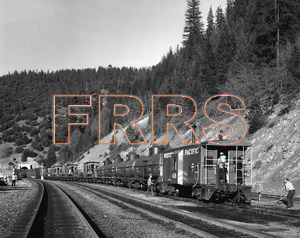

Speno Rail Grinding Train - Extra 702-West works its way at an average of two miles per hour over the WP main line in the Feather River Canyon

(Mileposts Winter 1967 - Spring 1977)

|

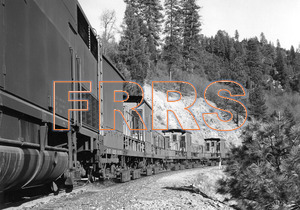

Speno Rail Grinding Train - In front of each grinding wheel is a hanging metal strip curtain to keep the metal shavings at track side.

(Mileposts Winter 1967 - Spring 1977)

|

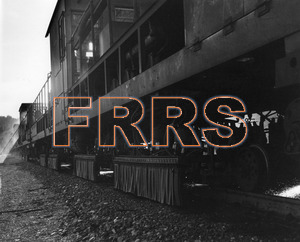

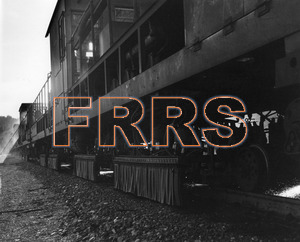

Speno Rail Grinding Train - Grinding operations proceed on a 12 hour day schedule, as rays of the sun set on the control cabs.

(Mileposts Winter 1967 - Spring 1977)

|

Speno Rail Grinding Train-07 Paul Gordenev

|

Speno Rail Grinding Train - Depending on the condition of the rail the pressure of the grinding wheels on the rail can be increased or decreased. It is easy to see the 'teeth' of the operation as shown in this photo. The 15·hp motor is weighted down on the rail grinding wheel. 48 of these wheels will grind each rail to a shiny smooth finish.

(Mileposts Winter 1967 - Spring 1977)

|

Speno Rail Grinding Train-09 Paul Gordenev

|

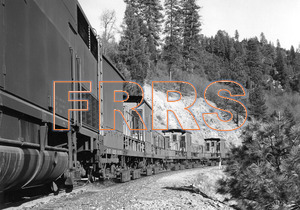

Speno Rail Grinding Train - The 11 car rail grinder train switches in to a siding at Keddie at the end of another 12 hour work day. Equipment is readied for the next day's assignment

(Mileposts Winter 1967 - Spring 1977)

|

Speno Rail Grinding Train-11 Paul Gordenev

|

Speno Rail Grinding Train-12 Paul Gordenev

|

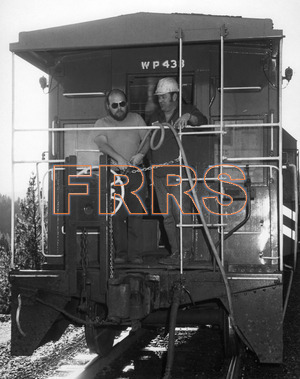

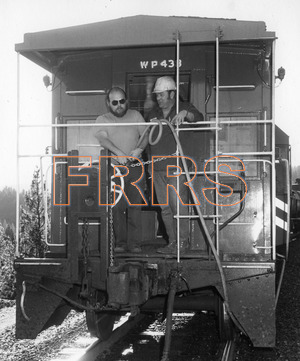

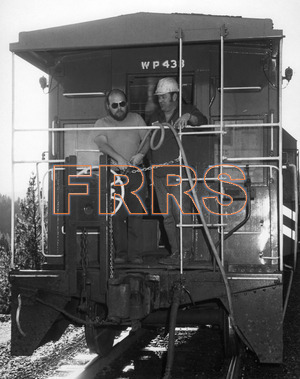

Speno Rail Grinding Train - Inspecting the rail grinding operations at the back of the special train are Ray Hobbs, WP's division engineer (Ieft·facing camera) and Chris Aadnsen, assistant division engineer (holding hose). This high pressure water hose provided additional fire protection if needed.

(Mileposts Winter 1967 - Spring 1977)

|

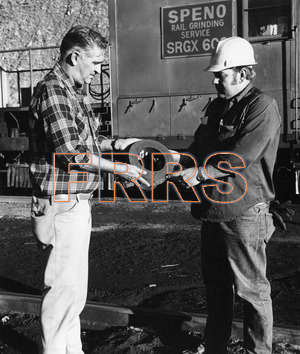

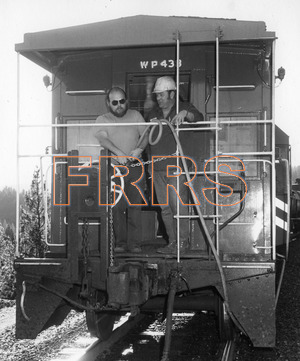

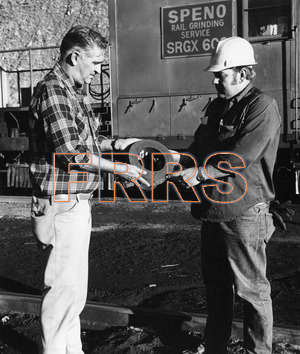

Speno Rail Grinding Train - Cliff A. Gerstner, WP's Engineer·Construction (left) and Jerry K. Packer, Speno Rail Grinder Foreman, hold a new grinding wheel to demonstrate the size and texture of the wheels used in the train.

(Mileposts Winter 1967 - Spring 1977)

|

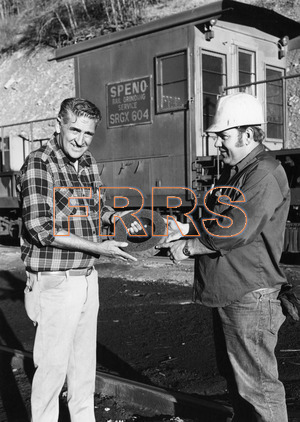

Speno Rail Grinding Train - Cliff A. Gerstner, WP's Engineer·Construction (left) and Jerry K. Packer, Speno Rail Grinder Foreman, hold a new grinding wheel to demonstrate the size and texture of the wheels used in the train.

Speno Rail Grinding Train-15 Paul Gordenev

(Mileposts Winter 1967 - Spring 1977)

|

Speno Rail Grinding Train-16 Paul Gordenev

|

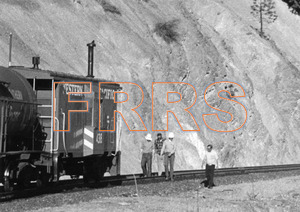

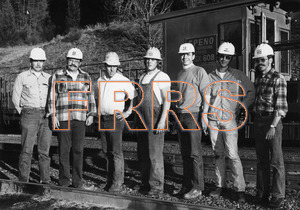

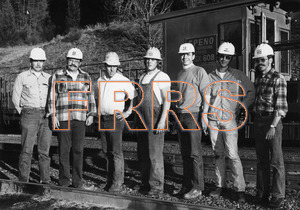

Speno Rail Grinding Train - Part of the Western Pacific team who worked with the rail grinding crew were the following: (left) Ken D. Sawyer, Roadmaster NCE; Dan W. Parnell, Bridge, Building & Track Inspector; D. R. Bradley, Track Rider; T. C. Schmidt, Track Rider; Chris Aadnsen, Asst. Division Engineer; Pat R. O'Kelly, Asst. Roadmaster; and Dennis G. Paul, Roadmaster Keddie.

(Mileposts Winter 1967 - Spring 1977)

|